Falco’s liquid/liquid separator

Why to use it:

Removes hydrocarbons, oil and grease from process water and wastewater.

Used as a pretreatment to enable separation without the use of chemical products.

Opportunity to reuse the separated products.

How it works:

The Falco’s separator works on a simple principle

The oily water is pumped tangentially in the widest part: the entrace of the cyclonic separator.

The centrifugal movement of oily water is accelerated as it moves down through the body conical,

pushing the heavier water against the outer walls, while the lighter oil moves towards the

center of the separator.

The separated oil is removed through the outlet at the top of the separator and the purified

water is discharged through the lower part of the separator.

Why this separator is so powerful?

Unlike the plate separators, the Falco’s separator is not based on gravity for separation.

The centrifugal force generated inside the vortex of the Falco’s separator is greater than 1000 times force of gravity.

With such force, even the emulsified oil droplets can be separated.

Advantages:

– Lower installation costs

– High quality construction

– High efficiency of separation

– Small footprint by 90% compared to conventional separators

– Wide range of capacities, from 2 to 100 m3

– full pneumatic functioning

– Minimum maintenance

COMMON APPLICATIONS

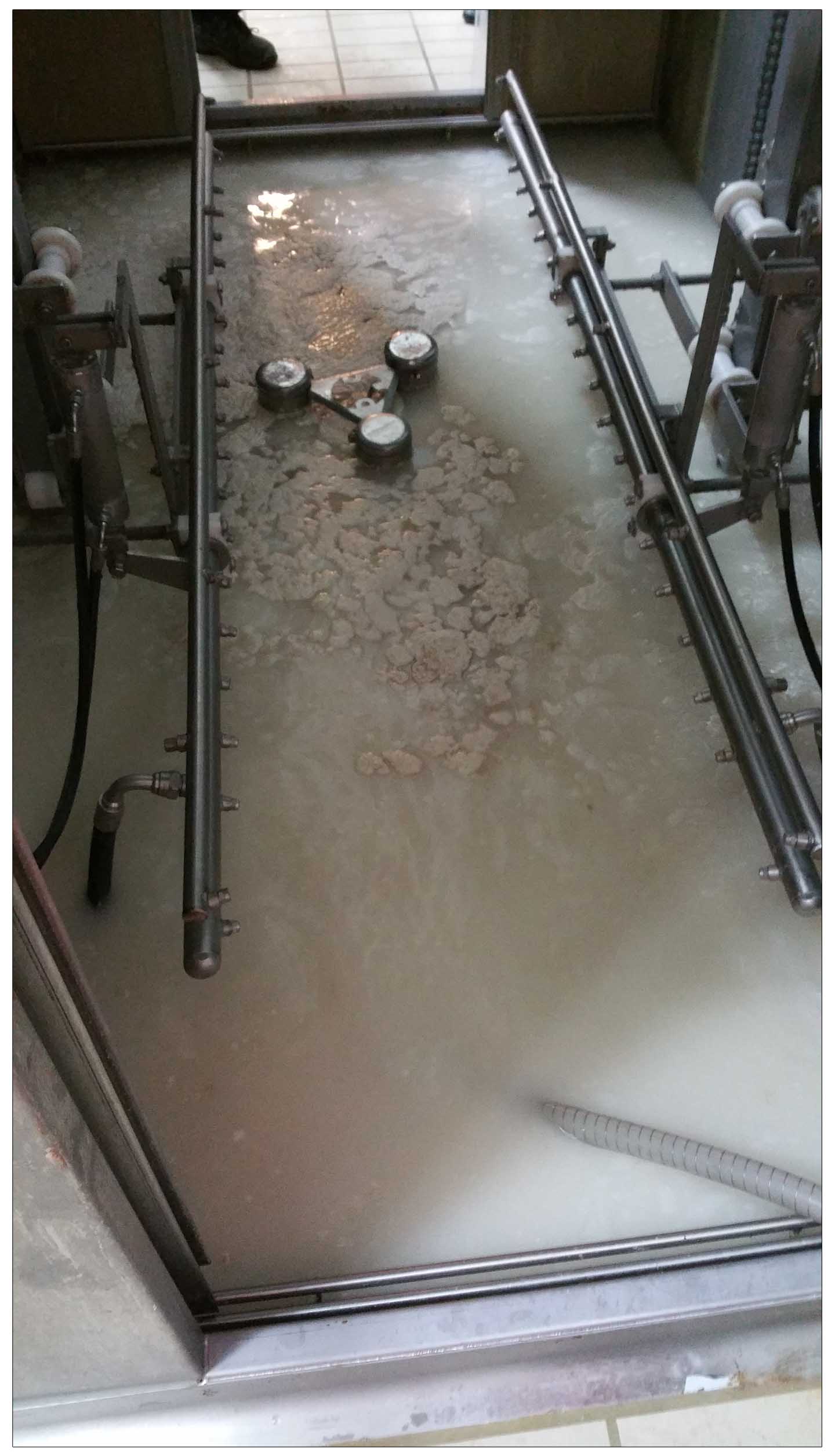

Oily Water Treatment

Die casting metals steel mills

Refueling facilities fuel storage

Washing water reuse Recovery suet and fat feed

Reduce COD and BOD without chemical additives Food production

Recovery tallow and fatty acids from meat processing waters Dairy effluents

Washing trains Pollution Prevention

Automotive

Features:

| Recycling Option – Allows very high separation efficiencies of 5-10 PPM – Possibility of increasing the recycling timing – Improve performance and meet future standards |

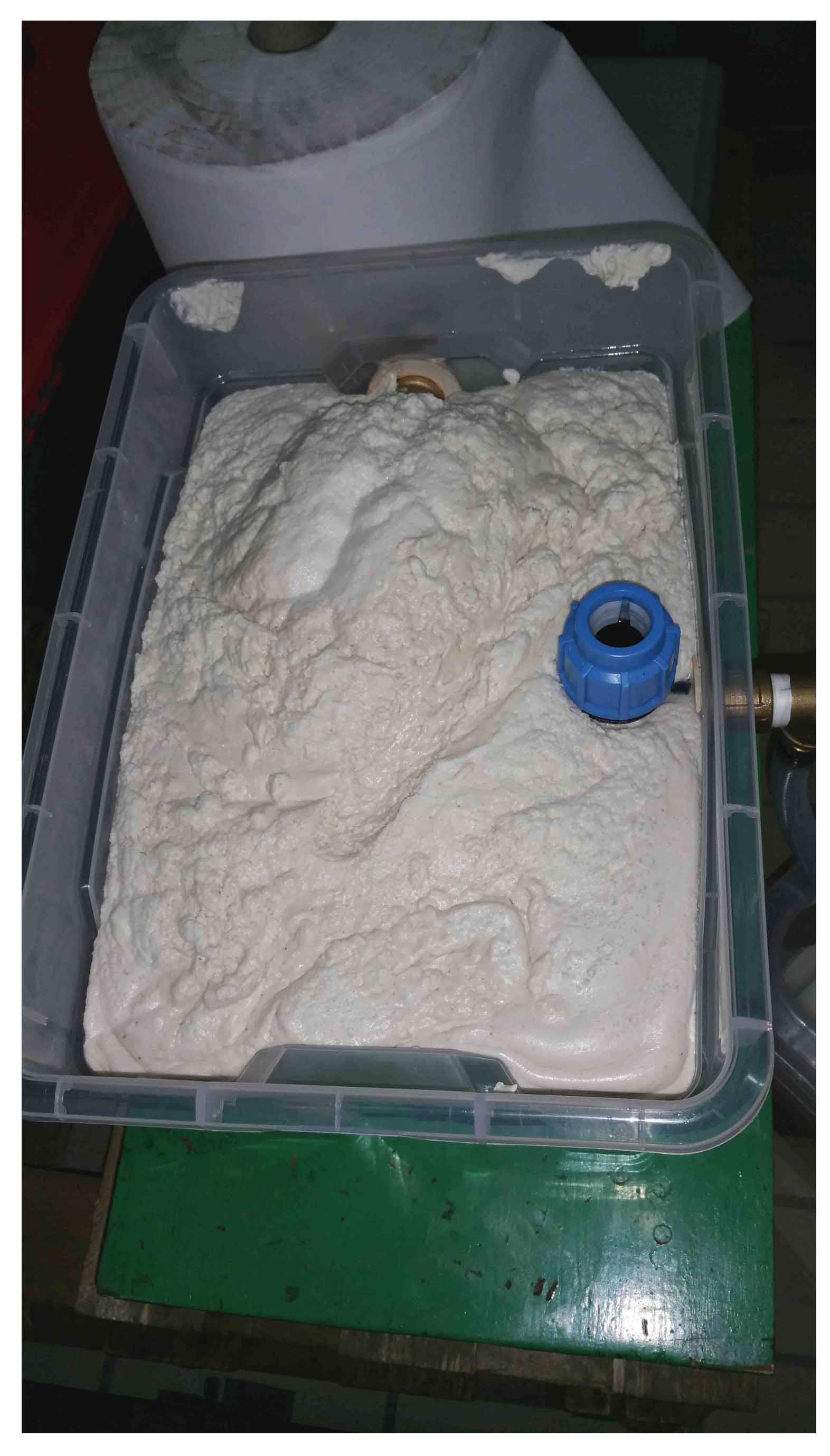

Oil storage and settling tank

– Concentrates and accumulates oil

|

| Pneumatic functioning

– Safe in classified areas

|

Pneumatic diaphragm pump

– Classified

|

| Solids filter

– Remove debris larger than 2mm

|

Oil skimmer

– Prevents stagnant and smelly oils to stratify

|